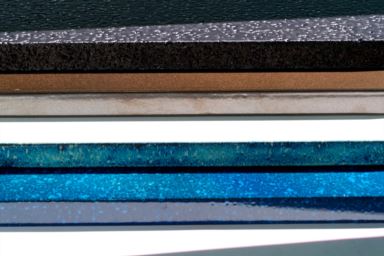

in particular: Sharp, a cutting and precise edge; Round, with softer and organic curves; Cut, an artistic and elegant interpretation of imprecision; Bevelled, raising the surface into an even more three-dimensional effect; Tapered, pointed towards the top; 45°, ending in a dynamic angle.

The edges can also be kept Cover-Less or treated in Covered-Up, giving life to different finishes and treatments.