Installation Advice for Lavastone Surfaces

Successful lavastone countertop installations begin long before the material arrives on site. Proper preparation ensures optimal results that showcase the material's beauty while maximizing its functional performance.

Cabinet preparation represents a critical foundation for successful installation. Ensuring cabinets are level, structurally sound, and properly secured prevents future issues that could compromise the countertop's integrity. For island applications, adequate support beneath seam locations prevents potential stress that could lead to problems over time.

Transportation planning requires careful coordination. Lavastone's weight and valuable finish necessitate appropriate handling equipment and trained personnel to move pieces safely from fabrication to installation. Professional installers use specialized equipment including A-frames, vacuum lifters, and proper edge protection to prevent damage during transit and placement.

Template creation ensures precise fit and proper placement of cutouts for sinks, faucets, and appliances. Digital templating technologies provide exceptional accuracy, accounting for wall irregularities, cabinet variations, and specific design requirements. This precision particularly matters for lavastone's clean, architectural lines where gaps or misalignments would be visually jarring.

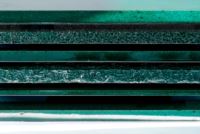

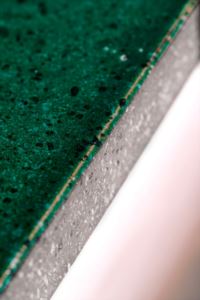

Seam placement strategy minimizes visual impact while ensuring structural integrity. Experienced fabricators locate seams away from high-stress areas and position them where they'll be least noticeable. For glazed lavastone, color-matched epoxy creates nearly invisible connections between pieces, maintaining the surface's visual continuity.

Edge finishing represents both technical and design considerations. Various edge profiles require specific fabrication techniques to ensure consistent quality throughout the entire perimeter. The edge treatment selected should complement both the overall design aesthetic and practical usage patterns of the space.

Post-installation inspection verifies proper fit, level placement, and seam quality. Immediately addressing any concerns prevents potential issues from developing over time. This quality control step ensures the finished installation meets both aesthetic expectations and functional requirements.